Dust Control in the Workplace

Numerous work activities generate dust, including cutting, sanding, demolishing, and drilling, making it a prevalent concern in many construction and manufacturing work environments.

The adverse health effects resulting from dust exposure, such as respiratory or gastrointestinal issues, may take years to manifest. This, compounded by the fact that dust particles are often imperceptible, means that dust-related problems are not always readily apparent.

So, what essential information do you need to know about managing dust in the workplace?

Why is dust a health concern in the workplace?

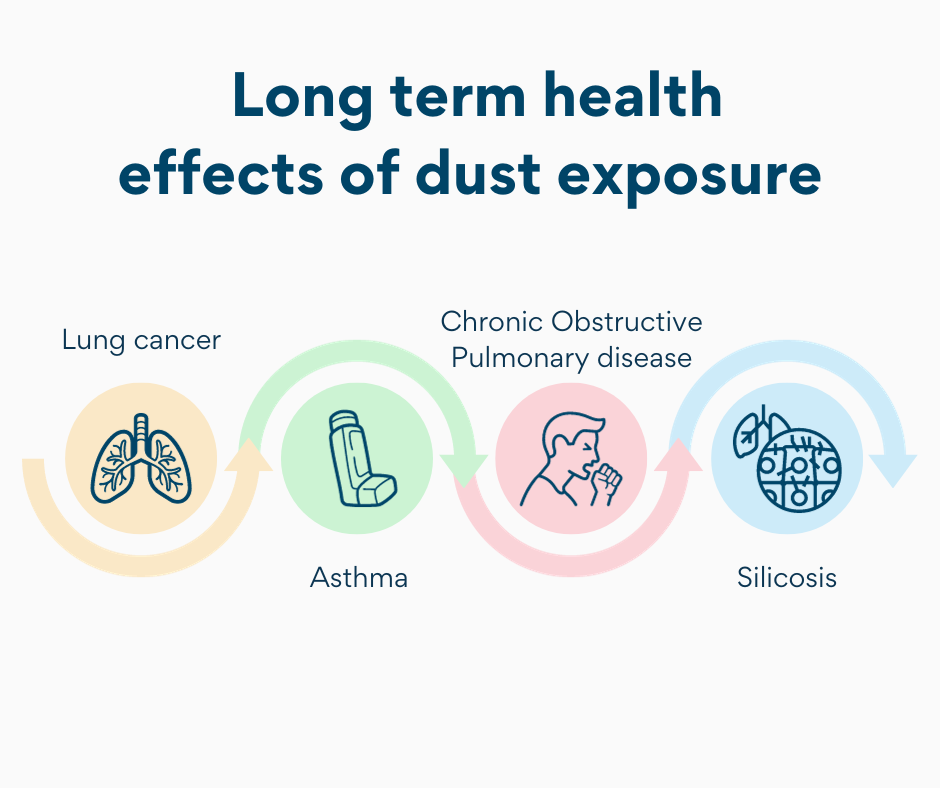

Dust can trigger an array of health problems. Some are immediately noticeable and short-term, like irritation of the eyes or skin. However, over time, dust accumulation can lead to long-term health issues that can significantly diminish a worker’s quality and duration of life. These chronic effects encompass conditions such as lung cancer, asthma, Chronic Obstructive Pulmonary Disease (COPD), and silicosis.

COPD comprises emphysema, which damages lung air sacs, and chronic bronchitis, characterized by persistent airway inflammation. Symptoms include escalating breathlessness, a chronic cough, recurrent chest infections, and persistent wheezing. These symptoms can markedly impact one’s quality of life and, when combined with frequent chest infections, potentially shorten life expectancy.

Silicosis is a protracted lung ailment resulting from prolonged inhalation of substantial amounts of silica dust. Once within the lungs, it induces inflammation and gradually leads to areas of hardened, scarred lung tissue (fibrosis). Lung tissue scarred in this manner loses its proper functionality.

These diseases can cause lasting disability and premature death. According to the HSE, it is estimated that over 500 construction workers succumb to silica dust exposure annually.

What are the employer’s responsibilities for safeguarding against workplace dust?

Under section 2 of the Health and Safety at Work Act (1974), every employer is obliged to ensure, to the extent reasonably practicable, the health, safety, and welfare of all employees. While the act provides additional details regarding training and maintaining a safe work environment, the pivotal point is that employers are legally mandated to manage dust and safeguard their workers to the best of their abilities.

The Control of Substances Hazardous to Health (2002) regulations further expound upon these duties. They stipulate that employers cannot undertake work that might expose employees to hazardous COSHH (Control of Substances Hazardous to Health) substances unless a suitable risk assessment has been conducted, and control measures have been implemented.

These regulations encompass the management of dust in the workplace due to the health hazards it presents.

How can dust be controlled in the workplace?

There are numerous strategies for mitigating and controlling dust. Some involve eliminating dust generation altogether. This might entail obtaining building materials of the appropriate size to obviate the need for cutting, adopting alternative fastening methods to circumvent drilling, or opting for less powerful tools, such as a block splitter instead of a cut-off saw.

Dust control methods may encompass the use of water to suppress dust clouds, on-tool extraction systems like Local Exhaust Ventilation (LEV) that directly attach to tools. LEV can also be employed at cutting stations or as stationary dust extractor units to curtail airborne dust levels.

Other straightforward measures include restricting the number of individuals in proximity to the task, rotating workers engaged in the task, and enclosing the work area to prevent dust dispersion.

Lastly, Respiratory Protective Equipment (RPE) can prevent dust from entering an employee’s airways. RPE options include air-fed hoods or snug-fitting particulate masks, which can be full or half masks. Regardless of the type of RPE used, it must be suitable for the dust type and quantity, appropriate for the task, worn correctly, and face-fitted if it’s a tight-fitting mask.